Although the chemical is very dangerous if it comes in direct contact with human skin, it plays an important role in the paper industry and in industry and agriculture throughout the market. So where are the chemicals stored? How to safely store chemicals? How can we keep it from going bad? Currently on the market, 1000-liter IBC plastic barrels are the choice of many companies because this type of IBC plastic barrel can ensure safety, protect the environment, and save costs for manufacturing companies. In this article, CRM (Vietnam) Chemical Technology Co., Ltd. will provide some detailed information on choosing IBC plastic barrels to store and transport chemicals.

What type of barrel is the 1000 liter IBC?

Most of these 1000 liter IBC plastic barrels are made of 100% HDPE virgin plastic pellets, imported and manufactured from the United States, Japan and the European Union, and manufactured on the world's leading machinery production lines. The plastic barrels are highly durable, have good impact resistance and have a frame made of high-quality, rust-resistant galvanized steel, creating a barrel shape that meets current chemical and liquefaction industry standards.

Plastic buckets that meet the standards are waterproof, UV-resistant, acidic and corrosive to toxic chemicals and can be safely used to store food. The product has a characteristic white color. With the above outstanding advantages, this barrel can be used in warehouses, factories, factories and other places with extremely harsh environments and high temperature places, and the durability of the product will not be affected even in rainy days and sunshine outdoors. Therefore, IBC plastic barrels have always been favored by chemical manufacturers. However, there are still some considerations that companies need to consider to choose which type of IBC plastic bucket is suitable for their products:

1. Determine the type of chemical and its properties:

Before purchasing an IBC plastic drum, you need to clearly determine the type of chemicals you need to store and transport. Chemicals with different properties require different types of drums. For example:

• Corrosive chemicals: For corrosive chemicals, you need to use container barrels made of wear-resistant materials such as polyethylene (PE) or polypropylene (PP), with a layer of wear-resistant material inside.

• Flammable chemicals: Flammable chemicals require that the drums are designed to be fireproof and have safety devices such as fire extinguishers.

• Biochemicals: For biochemicals, you need drums with special features to prevent the penetration of bacteria and viruses.

2. Capacity and size:

The 1000 liter plastic drum is usually chosen as it has a capacity suitable for many applications in most chemical manufacturing industries. However, each company needs to determine the quantity of chemicals to be stored and transported to select a container barrel with a more appropriate capacity to avoid problems during use.

3. Product materials and quality:

IBC plastic barrels can be made from many different types of plastic. For corrosive chemicals, polyethylene (PE) and polypropylene (PP) are popular choices because of their durability and good chemical resistance. In addition, the inside of the barrel is often made of special materials to ensure safety and contain chemicals.

4. Design and protective performance:

IBC plastic barrels are designed according to standards and include features to ensure safety during use and transportation:

• Safety valve: The valve helps control the pressure inside the barrel to avoid leaks or explosions

• Tight-fitting lid: A tight-fitting lid ensures that the chemicals inside are protected from any environmental exposure.

• Chemical liquid discharge mechanism: This structure helps you discharge chemicals easily and safely.

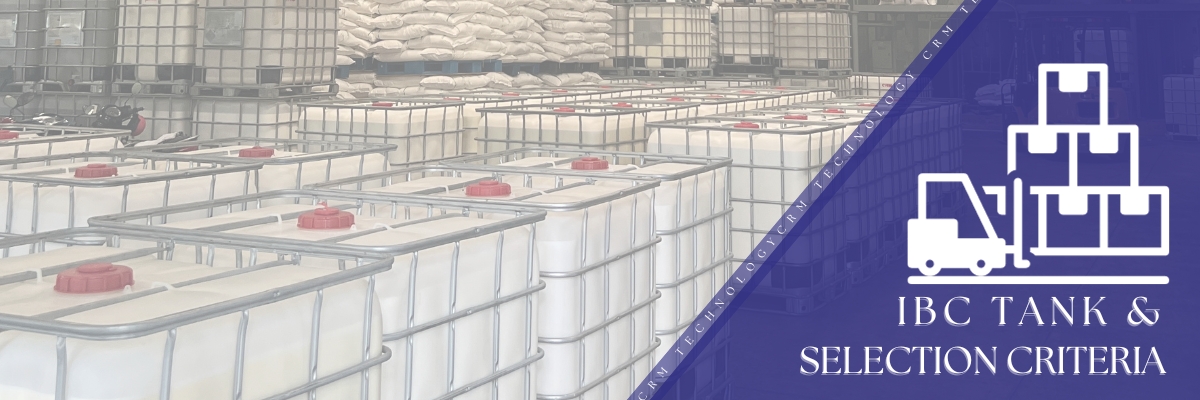

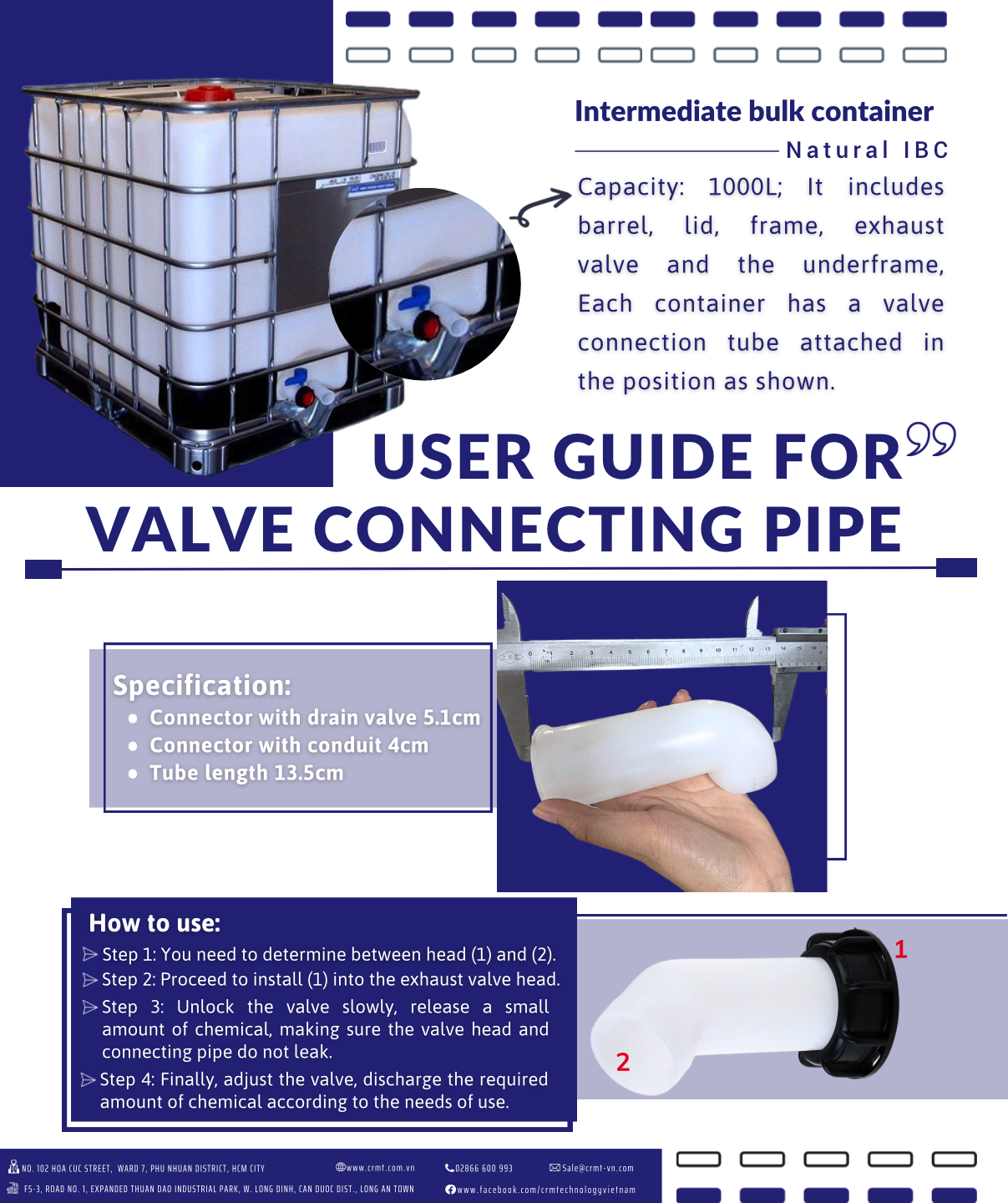

However, in some cases, the valve size will not match the piping of the chemical fluid delivery system. In order to overcome the above situation, CRM (Vietnam) Chemical Technology Co., Ltd. has attached white conduits before transporting and handing over chemicals to customers.

The following is a white catheter illustration and instructions on how to use the valve

Finally, make sure the IBC plastic bucket you choose complies with regulations and safety standards for your industry. This is especially important when you're transporting chemicals across borders or through areas with stricter regulations.

102 Hoa Cuc Street, Ward 7, Phu Nhuan District, Ho Chi Minh City

102 Hoa Cuc Street, Ward 7, Phu Nhuan District, Ho Chi Minh City (+84-272)3630828

(+84-272)3630828 +84 2866600993

+84 2866600993 sales@crmt-vn.com

sales@crmt-vn.com

Copyright 2021

CRM Technology (Vietnam) Co., Ltd

TOP