The phenomenon of foam formation during the production process has long been a persistent issue across various industries, including paint processing, food production, wastewater treatment, agriculture, and notably in the production of paper pulp and the treatment of paper production wastewater. Despite the existence of modern manufacturing technologies, foam formation remains prevalent during production. If these foam layers are not treated, they can pose specific challenges related to production and product quality. For instance, if the pulp stream contains air bubbles, foam marks may be left on the paper surface, hindering water drainage on the wire mesh. Additionally, air bubbles can increase the aggregation of pulp fibers, resulting in uneven paper formation and a rough paper surface, diminishing aesthetics and the desired quality of the product.

Furthermore, with the rapidly growing demand for paper production, foam in paper production wastewater not only affects the operation of wastewater treatment equipment but also directly impacts the overall water environment. For example, when using activated sludge processes to treat wastewater, a significant amount of foam is generated, covering the surface during air sparging and making the oxidation process more challenging, affecting the development of microorganisms. Therefore, addressing foam-related issues in the paper production process is a top concern for businesses. As a result, Silicone anti-foam agents are prioritized to address these challenges and produce the highest quality products to meet customer needs. The following introduces the operation of this product:

What is a Silicone anti-foam agent, and how does it work?

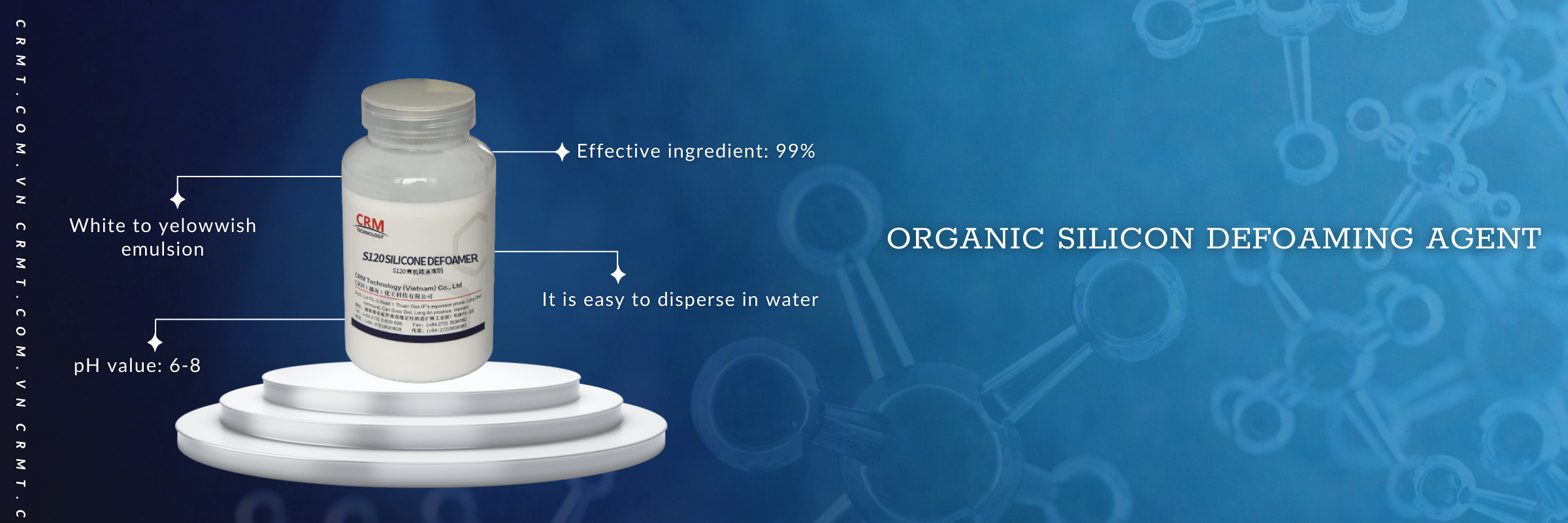

Silicone anti-foam agent is highly effective and possesses various superior properties. In terms of appearance, the product is in the form of white or light yellow flakes, with a pH level of approximately 6-8, achieving up to 99% efficiency.

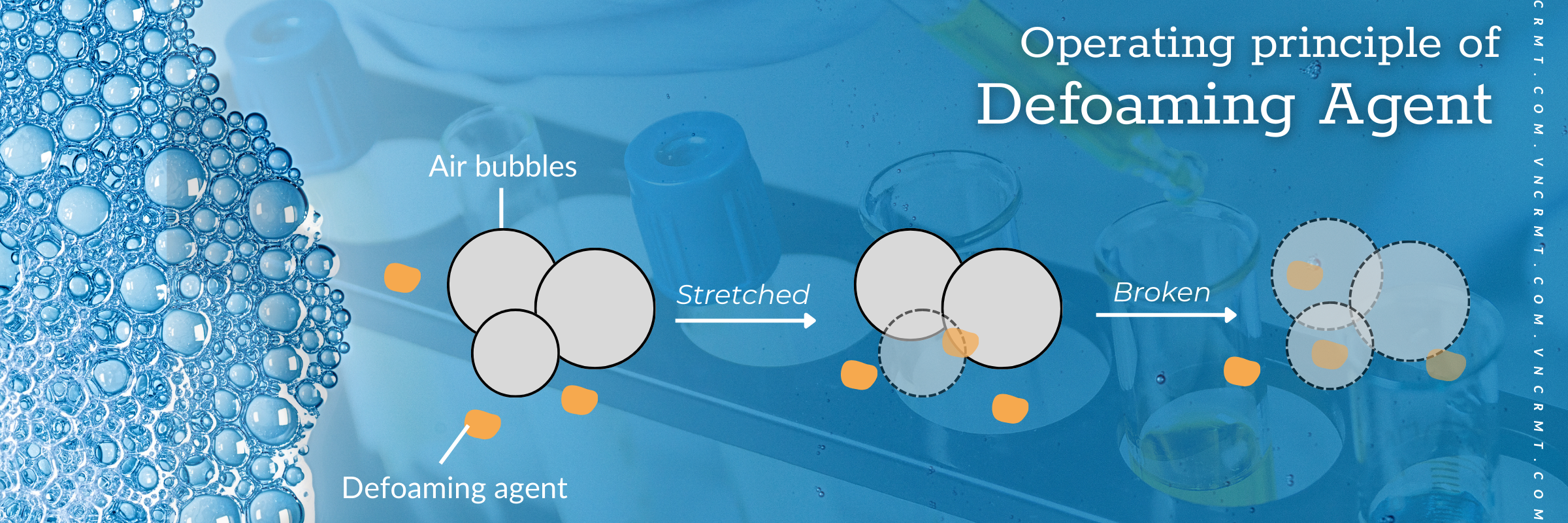

The working principle involves three criteria: "Permeate - Stretch - Break." The foam-breaking agent helps break up gas bubble clusters formed during production and has the ability to limit the formation of new foam.

2. Characteristics of Silicone anti-foam agent.

Silicone anti-foam agents exhibit outstanding characteristics and advantages, such as:

Wide range of applications: Due to the unique chemical structure of Silicone, it is incompatible with water or substances containing polar groups, as well as hydrocarbons or organic substances containing hydrocarbon groups. Its versatility allows it to be used for foam control in water and oil systems.

Strong anti-foam ability: It not only efficiently breaks existing foam but also inhibits and prevents foam formation. It requires a small amount, with just a fraction of the weight of the foam-forming medium enough to produce a foam-breaking effect, providing cost-effectiveness and minimal pollution.

Low surface tension: The surface tension of Silicone is typically 20-21 dynes/cm, lower than water (72 dynes/cm) and common foaming liquids, making it an effective anti-foam agent.

Good thermal stability: Using Silicon Dimethyl as an example, it can withstand prolonged exposure to 150°C and short-term exposure to over 300°C without breaking down its Si-O bond. This ensures that Silicone foam-breaking agents can be used in a wide temperature range.

Good chemical stability: Due to the relatively stable Si-O bond, Silicon compounds have high chemical stability and low reactivity with other substances. This allows Silicone anti-foam agents to be used safely in systems containing acids, alkalis, and salts.

Physiologically inert: Silicon has been proven non-toxic to humans and animals, with a lethal dose greater than 34 g/kg. Therefore, Silicone foam-breaking agents (when combined with non-toxic emulsifiers) can be safely used in industries such as food, medical, pharmaceuticals, and cosmetics.

Silicone anti-foam agents function to break and inhibit foam, and they can be used directly or diluted. If the foam-producing system can be stirred and dispersed, the anti-foam agent can be added directly without dilution. If dilution is necessary, it should be done according to the instructions. Dilution with water or other products may lead to layer separation, affecting product effectiveness. Depending on different usage conditions, the dosage can be adjusted from 10-100 ppm for foam breaking.

Understanding the essential role of anti-foam agents in the manufacturing industry and aiming to meet market demands, CRM Technology Co., Ltd. (Vietnam) is offering the anti-foam product line "S120 Silicone Defoaming Agent." The product is a synthesis of polysiloxane, dispersants, and stabilizers. Additionally, S120 is compatible with foam-producing environments, exhibiting fast defoaming and effective dispersion in water. For optimal product condition, it should be stored at a suitable temperature between 5-30°C, avoiding high temperatures and sunlight exposure. Avoid contact with acidic, alkaline, or salt substances. When not in use, ensure tight sealing to prevent bacterial contamination. In case of separation, thorough stirring is recommended, with no impact on quality and effectiveness. Note that below 0°C, S120 may solidify, if this occurs, thaw and stir evenly without compromising product quality and performance.

For more detailed information, please contact us at hotline 02866600993 or email sales@crmt-vn.com for prompt advice and support.

102 Hoa Cuc Street, Ward 7, Phu Nhuan District, Ho Chi Minh City

102 Hoa Cuc Street, Ward 7, Phu Nhuan District, Ho Chi Minh City (+84-272)3630828

(+84-272)3630828 +84 2866600993

+84 2866600993 sales@crmt-vn.com

sales@crmt-vn.com

Copyright 2021

CRM Technology (Vietnam) Co., Ltd

TOP